Pro Coat Auckland Ltd is New Zealand's only official applicators of Tech Line Coatings

including a range of top quality performance coatings.

We can apply the following coatings:

Thermal Management, Thermal Barriers, Dry Film Lubricants, Thermal Dispersents

Pro Coat has available the full ‘Powerkote’ range of performance coatings, including the ferrous and non-ferrous thermal barrier coatings. These coatings, when applied correctly provide an unrivaled layer of thermal protection to piston tops, aluminum or cast iron combustion chambers, stainless, inconel, or titanium valves, and intake or exhaust ports.

The use of Zirconium in this coating gives it characteristics shared by no other product, Zirconium ‘moves’ heat, reducing detonation and increasing the effective oxidation of fuel.Zirconium is not subject to cracking and flaking, which can lead to extensive engine damage; in fact Zirconium actually strengthens the coated part.

During testing when sufficient heat was applied to a piston to melt aluminum, the Zirconium did not melt; in fact it helped to hold the softer aluminum together!

Look out for the Pro Coat display trailer at shows or call in anytime and see what we do. You will be surprised what a difference we can make to your old looking parts. Also check out our gallery for an indication of what is possible.

(Click here for a PDF version)

Cermakrome

Cermakrome is the most popular of the exhaust coatings. It gives the Polished aluminium look and sets of any engine bay. Cermakrome is used not only for thermal management but is fantastic for appearance i.e. intake manifolds age and oxidize when coated hold there shiny appearance.

Another area widely used is steel rims (truck rims) which gives the rim a alloy appearance.

Cermakrome is a metallic ceramic coating which greatly improves exhaust corrosion-resistance and exhaust gas velocity, while reducing under bonnet temperatures.

Black Satin

Black Satin is a ceramic reinforced coating designed for high temperature applications like cermakrome which reduces exhaust manifold surfaces and under bonnet temperatures.

Black Satin withstands 2000f temperatures

Thermal Barrier Coatings (TBC)

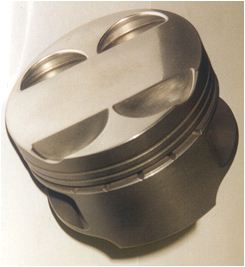

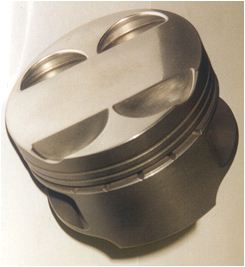

CBC2 Powerkote and CBX Powerkote are Cermet Coating Thermal Barriers. TBC coatings create thermal protection to piston tops, combustion chambers, valves, intake and exhaust ports.

The Piston is one of the very first parts that should be considered for coating.

Coating the Piston reduces friction and wear, reduces part operating temperature, can increase horsepower and torque, reduce or eliminate detonation, allow higher compression ratios to be utilised and allow tighter to wall clearances for a better ring seal.

Dry Film Lubricant

Dry Film Lubricant (DFL) is a moly based coating capable of providing lubrication at levels as high as 350,000 psi. High pressure lubrication is a must for any performance engine. Typical uses would be piston skirts, engine bearings, valve stems, valve springs and all moving gear componentry.

Obvious reasons for the coating are to reduce friction, inhibiting galling and seizing.

By applying a Dry Film lubricant, friction, galling and wear are reduced. The lubricants are capable of carrying loads beyond the crush point of the Piston. In addition, the lubricants are "fluid retaining" materials that actually hold oil to the surface beyond the pressure wher the oil would normally be squeezed off.

The ability to carry greater loads, up to 350,000 PSI, while increasing lubricity (reduced friction) allows tighter piston to wall clearances to be run. This leads to better sealing with no increase in friction.

Thermal Dispersents (TLTD)

This thermal management system (TLTD) is a coating developed for enhancing heat transfer.

This product transfers heat faster than the bare metal surface, not just a black body heat emitting coating. With special ingredients that contribute to heat flow and added corrosion protection make this product very effective on brakes, intake manifolds, cyclinder heads, oil pans, radiators and intercoolers.

By applying TLTD to the underside of the Piston, oil that is splashed onto the Piston to cool it will shed rapidly. Heat transfers most rapidly when there is a large difference in temperature.

The longer oil clings to a hot surface the hotter the oil becomes. By shedding the cooling oil more rapidly, cooler oil is splashed over the surface more frequently.

If the oil "hangs" longer, it absorbs less heat and blocks cooler oil from contacting the hot surface. A cooler Piston grows less, allowing tighter Piston to wall clearances.

Radiators and other Coolers such as Oil and Transmission Coolers will benefit from the applciation of Tech Line's TLTD Thermal Dispersant. These units are designed to help cool the fluid going through them whether it is water, oil or transmission fluid.

By coating the Radiator, we are going to enhance the ability of the unit to transfer heat. It is going to act like it is a bigger unit than it actually is. We do this by enhancing the capability of the surface to transfer heat into the airstream to the air flowing over the fins.

This coating can also be used on Oil Pans, Rearend Housing and Transmission Cases. Any surface where it is desirable to see heat radiated away from, the TLTD will enhance the ability of that unit. Radiators and Coolers especially benefit from this.